Understanding Metal Characteristics for Laser Cutting

Yo, listen up, metalheads! Let’s dive into the nitty-gritty of metal characteristics for laser cutting. We’re talkin’ about the lowdown on different metals and how they play with the laser game. From conductivity to reflectivity to thermal conductivity – these factors ain’t just fancy words, they’re the keys to unlockin’ the power of laser cutting, ya dig?

Mastering Metal Laser Cutting Basics

- Laser-cutting Metal 101

- Perks of Laser-cutting Metal

- Must-know Gear for Laser Metal Cutting

Now, here’s the kicker – metal characteristics ain’t just for show. They can make or break your laser cutting game, fam. Mess with the conductivity or thermal conductivity, and you could end up with some wonky cuts or even damage your machine. So next time you’re slicin’ and dicin’ with your laser cutter, keep these metal traits in mind and make sure you’re playin’ by the rules of the metal game! 🤘🔥

Optimizing Laser Parameters for Different Metal Types

First off, let’s break it down – why does it even matter? Well, my dudes, different metals have different properties, and that means they react differently to the laser beam. So if you’re cuttin’ through some thick steel versus a thin sheet of aluminum, you’re gonna need to adjust your settings accordingly. It’s like pickin’ the right tool for the job – you wouldn’t use a hammer to screw in a bolt, right?

Picking the Perfect Metal for Laser Cutting

- Stainless Steel Swag

- Aluminum Alloy Action

- Carbon Steel Coolness

Now, let’s talk shop. Laser power, speed, and frequency – these are your weapons of choice in the battle against metal. Crank up the power too high, and you’ll end up with a melted mess. But go too slow, and you’ll waste time and risk damaging your material. It’s all about findin’ that sweet spot – the Goldilocks zone of laser parameters that gives you clean, precise cuts every time. So next time you’re in the laser lab, don’t be afraid to experiment and find what works best for your metal masterpiece! 🚀🔥

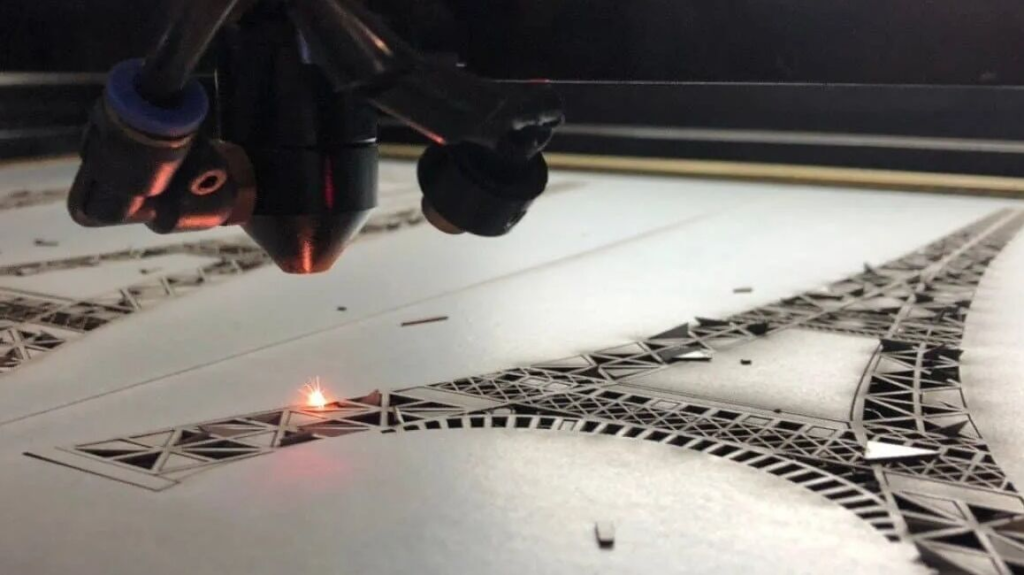

Specialized Techniques for Complex Metal Designs

Alright, metal maestros, it’s time to level up your laser game with some next-level techniques for tackling those intricate designs. We’re talkin’ about goin’ beyond the basics and delvin’ into specialized methods that’ll take your metal creations to the next dimension. So grab your goggles and let’s dive deep into the world of complex metal cutting and engraving!

Bossing it with Laser-cutting Skills

- Dialing in Laser Parameters

- Getting Crafty with Cutting Styles

- Ditching Distortion and Dealing with Debris

But wait, there’s more! Ever heard of edge taper correction? It’s like magic for your metal cuts, my dudes. With edge taper correction, you can compensate for the natural taper that occurs when cuttin’ thick materials with a laser. That means you can achieve straight, uniform edges on even the thickest of metal sheets, no sweat.

And last but not least, let’s talk kerf compensation. Sounds fancy, right? Well, it is! Kerf compensation is all about adjustin’ your laser settings to account for the width of the laser beam, so you can ensure your cuts come out the exact size you want ’em. It’s like havin’ laser precision down to the micron, my friends. So next time you’re pushin’ the limits of metal design, don’t forget to bust out these specialized techniques and take your creations to new heights! 🛠️🔥

Finishing Touches: Elevating Laser-Cut Metal Surfaces

Exploring Metal Etching and Marking

- Metal Marking Mastery

- Tagging Metal for Various Vibes

- Techniques for Tough Metal Markings

First off, let’s talk about deburrin’. You’ve just sliced through some metal like butter with your laser cutter, but now you’re left with those pesky burrs along the edges. Fear not, my friends, deburrin’ is here to save the day! Whether you’re usin’ a hand tool or a fancy deburrin’ machine, gettin’ rid of those burrs will give your metal parts that clean, professional finish you’re lookin’ for.

But wait, there’s more! How about cleanin’ and degreasin’ those metal surfaces? After all, nobody wants their laser-cut masterpiece lookin’ all grungy and greasy. A quick wipe-down with some solvent or a dunk in a degreasin’ bath will have your metal parts lookin’ shiny and new in no time.

And last but not least, let’s talk surface finishin’. Whether you’re goin’ for a brushed, polished, or textured look, there’s a surface finish out there to suit every style. So bust out those sanders, buffin’ wheels, or chemical treatments and get creative with how you wanna make your metal shine. With the right finishing touches, your laser-cut metal creations will be the talk of the town! 🌟🔩

Industry-Specific Applications of CNC Laser Cutting

First up, let’s talk about aerospace. Yeah, you heard me right – aerospace! CNC laser cutting is playin’ a major role in the production of aircraft components, from lightweight fuselage panels to precision-engineered engine parts. With CNC laser cutters, aerospace manufacturers can churn out parts with unparalleled accuracy and consistency, helpin’ to keep planes flyin’ high and safe in the sky.

Unleashing Advanced Metal Laser Cutting Features

- Autofocus Fusion

- Spin and Win: Rotary Add-ons

- Expanding Laser Processing Possibilities

And let’s not forget about architecture and construction. With CNC laser cutting, architects and builders can bring their wildest design fantasies to life, creatin’ awe-inspirin’ structures and facades that push the boundaries of what’s possible. From intricate metal screens to massive steel beams, CNC laser cutting is helpin’ to shape the skylines of tomorrow.

So whether you’re flyin’, drivin’, or just admiring the view, chances are CNC laser cutting has had a hand in makin’ it happen. It’s not just a technology – it’s a game-changer, my friends. And the best part? We’re just gettin’ started! 🚀🔥

Integration of CNC Laser Cutting with Other Manufacturing Processes

Alright, fam, let’s talk about how we can take CNC laser cutting to the next level by mixin’ it up with some other dope manufacturing processes. We’re talkin’ about combin’ CNC laser cuttin’ with stuff like welding, bendin’, and even 3D printin’ to create some seriously mind-blowin’ stuff. So buckle up, ’cause we’re about to dive into the world of hybrid manufacturin’!

Safety First: Laser Metal Cutting Protocols

- Vents and Gear for Safety Sake

- Rocking Personal Protective Gear (PPG)

- Metal and Laser Safety Hacks for Cool Cats

First things first, let’s talk about weldin’ and laser cuttin’. These two go together like peanut butter and jelly, my friends. By combin’ laser cuttin’ with weldin’, you can create complex metal structures and components with ease. Plus, with laser precision, you can ensure that your welds are clean, strong, and straight-up beautiful.

But wait, there’s more! How about bendin’ and laser cuttin’? Now we’re talkin’! By integratin’ laser cuttin’ with bendin’ techniques, you can create all sorts of cool stuff, from intricate metal brackets to sleek sheet metal enclosures. Plus, with CNC control, you can bend with precision, accuracy, and speed, makin’ your workflow smoother than a fresh jar of Skippy.

And let’s not forget about 3D printin’ and laser cuttin’. These two technologies might seem like they’re from different planets, but when you bring ’em together, magic happens. By usin’ laser cuttin’ to prep materials or add fine details to 3D-printed parts, you can create hybrid creations that are truly out of this world.

So whether you’re weldin’, bendin’, or 3D printin’, don’t be afraid to mix it up with CNC laser cuttin’. ‘Cause when you combine these bad boys, the possibilities are endless, and the results are straight-up amazin’! 🛠️🔥

Economic and Environmental Considerations in Laser Metal Cutting

Alright, squad, let’s get real for a sec and talk about the green and the mean – yeah, we’re talkin’ cash money and savin’ the planet, all in one. When it comes to laser metal cuttin’, there’s more to it than just makin’ cool stuff – we gotta think about the bottom line and the environment too. So grab your shades, ’cause we’re about to dive into the world of economic and environmental savvy!

| Networking and Community Building | Connect with Fellow Laser Cutters Online | Join Forums and Groups for Tips & Tricks | Collaborate on Cool Laser Projects |

| Hang Out in Laser-cutting Communities | Get Social on Laser-cutting Forums | Team Up with Like-minded Makers | Share Experiences and Learn Together |

| Attend Laser-cutting Meetups | Engage with Laser-cutting Enthusiasts | Seek Advice and Share Insights | Work Together on Exciting Projects |

| Organize Laser-cutting Workshops | Build Your Network in the Laser Community | Discuss Techniques and Innovations | Pool Resources for Bigger Ventures |

| Participate in Laser-cutting Challenges | Show off Your Skills and Learn from Others | Exchange Ideas and Troubleshoot Issues | Foster a Supportive Laser Community |

| Explore Laser-cutting Events and Expos | Stay Updated with the Latest Trends | Find Inspiration and New Opportunities | Form Lasting Connections and Friendships |

But hold up, ’cause we ain’t done yet. Let’s talk about the planet, ’cause she’s kinda important too. Laser metal cuttin’ ain’t just good for your wallet – it’s good for Mother Earth too. By cuttin’ down on material waste and energy usage, you’re doin’ your part to reduce your carbon footprint and keep our planet green and clean. So next time you fire up that laser cutter, pat yourself on the back – you’re not just makin’ cool stuff, you’re makin’ a difference.

Future Trends and Innovations in Metal Laser Cutting Technology

Alright, peeps, let’s take a trip to the future and see what’s cookin’ in the world of metal laser cuttin’. We’re talkin’ about the latest and greatest tech that’s gonna take our metal-cutting game to a whole new level. So strap in and get ready for a wild ride through the cutting-edge world of laser tech!

First up, let’s talk about ultrafast lasers. These bad boys are like the speed demons of the laser world, pumpin’ out pulses at insane speeds that’ll make your head spin. With ultrafast lasers, you can cut through metal faster than ever before, makin’ your production process smoother than a fresh jar of peanut butter.

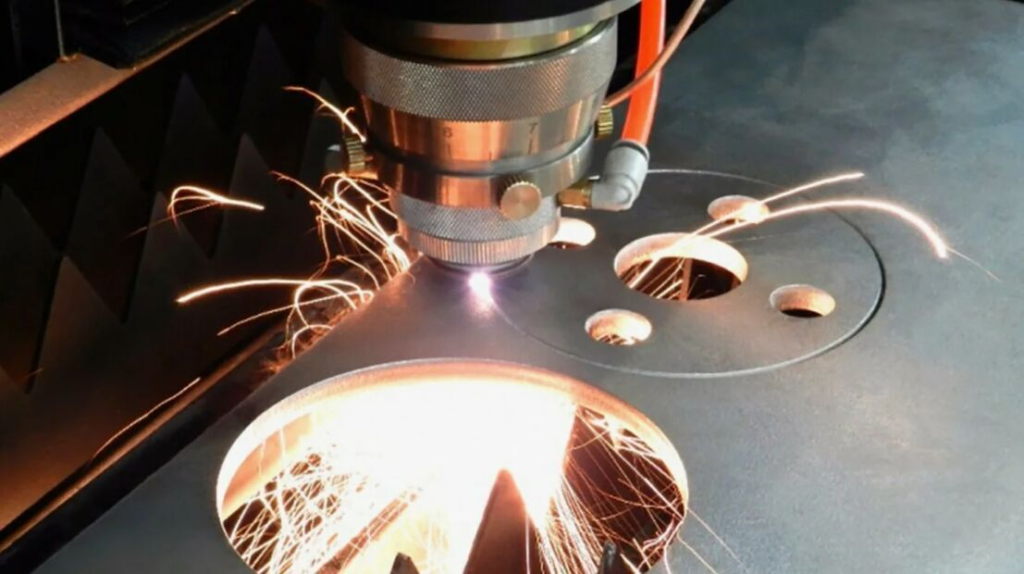

But that ain’t all – how about hybrid laser systems? Now we’re talkin’! By combin’ lasers with other cutting technologies like waterjet or plasma, you can create hybrid systems that offer the best of both worlds. That means you can cut through thicker materials with ease and precision, openin’ up a whole new world of possibilities for metal fabricators everywhere.